In the grain packaging process, the 50 lb bag packing machine plays an important role. It provides an efficient and precise bagging solution to help grain processors, farms and wholesalers increase productivity.

The 50 lb bag filling machine is a bagging equipment that uses advanced automation technology to quickly and accurately fill grain into 50 lb bags. The following is its detailed working process:

Raw material supply

The bagging machine receives the grain material through the material conveying system. This can be a feed hopper or a conveyor belt system that conveys the grain to the feed opening of the bag filling machine in a controlled manner. The design of the supply system can ensure uniform material supply to improve the efficiency and accuracy of bagging.

Bag positioning

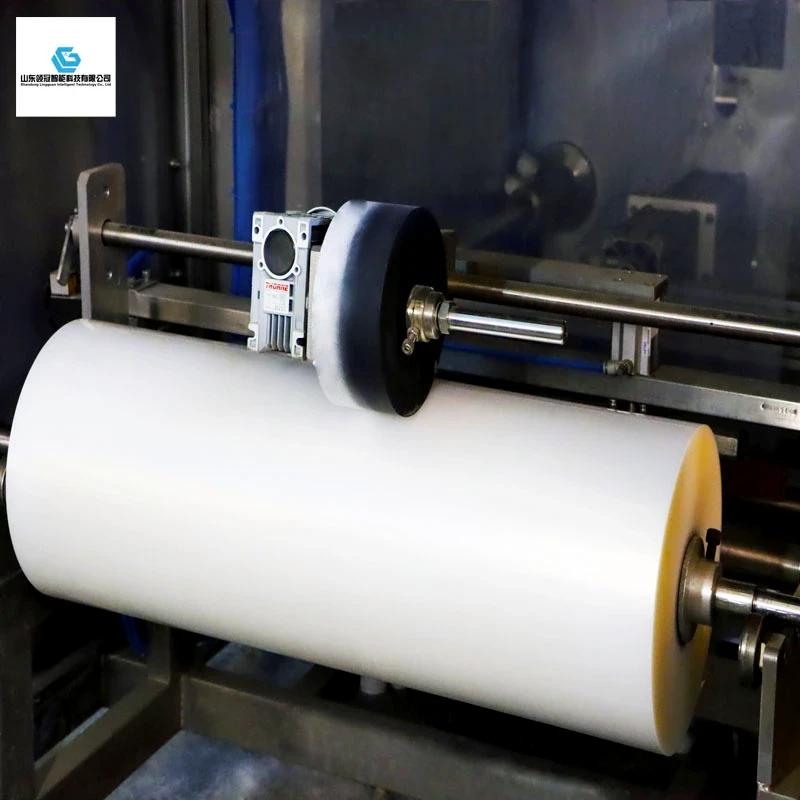

The bagging machine introduces the empty bags into the bagging area via a conveyor belt system. These bags are usually pre-made and positioned at appropriate intervals on the conveyor belt. Sensors or vision systems can be used to detect and confirm bag position, ensuring accurate filling.

Filling and metering

After the bag is positioned, the bag filling machine starts filling the bag with grain. It is equipped with a metering system to ensure that the grain weight in each bag reaches the preset target value. Common metering methods include gravimetric sensors, flow controllers, or volumetric gauges. Through real-time monitoring and feedback control, the bagging machine can adjust the material flow to achieve accurate bagging.

Sealing and discharging

When the bag reaches the target weight, the bag filling machine feeds it into the sealing area. The closure system seals the opening of the bag to ensure the airtightness and freshness of the cereal. After the seal is completed, the bag moves out of the bag filling machine via a conveyor belt system and is ready to be discharged to the next stage of processing or transport.

These steps are usually carried out under an automated control system that can be set and adjusted as needed. This advanced bagging technology increases bagging speed, accuracy and efficiency, reducing the risk of human error and material waste.

By using the 50 lb bag filling machine, grain processors, farms and wholesalers can achieve efficient and accurate bagging of grain, increasing production efficiency and ensuring product quality. This automated bagging technology has a wide range of applications in the field of grain packaging, bringing convenience and a competitive advantage to the grain processing and distribution industry.

Key features of the 50 lb bag filling machine help improve bagging efficiency and accuracy:

High-speed bagging

50 lb bag filling machines typically have high speed bagging capabilities and can handle high volume grain packing needs. Its efficient bagging speed can greatly improve production efficiency and reduce bagging time and labor costs.

Accurate metering

In order to ensure that the grain weight in each bag is accurate, the 50lb bag filling machine is equipped with a sophisticated metering system and weighing equipment. These devices monitor and measure the weight of the grain in real time through technologies such as weight sensors, flow controllers or volumetric gauges. Accurate dosing prevents over- or under-filling bags, ensuring each bag has the preset target grain weight.

Automatic control

The 50lb bag packing machine is equipped with an advanced automatic control system, which has the function of monitoring and adjusting key parameters. These systems can monitor parameters such as the operating status of the bagging machine, material flow and bagging speed in real time. According to the set parameters and preset goals, the automatic control system can automatically adjust the key parameters in the bagging process to ensure the stability and consistency of bagging.

Diversified packaging formats

The 50 lb bag packer has flexible configuration options to accommodate different packaging format requirements. It can be applied to various bag types such as paper bags, woven bags or plastic bags. This flexibility allows companies to choose the appropriate packaging format according to market demand and provide a variety of product packaging options.

To sum up, the key features of the 50lb bag packing machine include high-speed bagging, precise metering, automated control, and diverse packaging formats. These features make the 50lb bag filling machine an indispensable bagging equipment in the grain packaging process, improving bagging efficiency, precision and flexibility. Whether it is a grain processing company, a farm or a wholesaler, the use of a 50lb bag filling machine can improve the quality and production efficiency of grain packaging to meet different market needs.

Specific case

"GrainPro Farms," a farm focused on grain processing and distribution, uses a 50-pound bag filling machine in its production line. The bagging machine has a high-speed bagging capacity of 1000 bags per hour and can accurately measure the weight of grain in each bag. By employing an automated control system, GrainPro Farms has achieved an efficient and trouble-free bagging process, improving production efficiency and product quality. They are also able to flexibly adapt to different packaging needs, using paper bags or woven bags to meet the diverse requirements of the market.

FAQ

Q: What is a 50 lb bag filling machine for grains packing?

A: A 50 lb bag filling machine for grains packing is a specialized machine used in the agricultural industry to automatically fill 50-pound bags with various types of grains, such as rice, wheat, corn, or barley.

Q: How does a 50 lb bag filling machine work?

A: The machine typically consists of a hopper that holds the grains, a weighing system to ensure accurate filling, a conveyor or chute to direct the grains into the bags, and a sealing mechanism to close the bags once they are filled. The machine is often automated and controlled by a control panel.

Q: What are the main features of a 50 lb bag filling machine?

A: The features of a 50 lb bag filling machine can vary depending on the specific model and manufacturer. However, common features may include a high-speed filling capability, a precision weighing system, adjustable bagging speeds, bag clamps or holders, and a user-friendly interface for operation and settings adjustment.

Q: What types of grains can be packed using a 50 lb bag filling machine?

A: A 50 lb bag filling machine is designed to pack a wide range of grains, including but not limited to rice, wheat, corn, barley, oats, and millet.

Q: Is the machine suitable for other types of products or bag sizes?

A: While a 50 lb bag filling machine is primarily designed for 50-pound grain bags, some models may have adjustable settings to accommodate different bag sizes or even handle other products like seeds, animal feed, or granular materials. It is important to check the specifications of the specific machine you are considering.

Q: What are the advantages of using a bag filling machine?

A: Using a bag filling machine offers several advantages, including increased efficiency, improved accuracy in bag weight, reduced labor requirements, consistent and uniform bag filling, minimized product waste, and improved overall packaging productivity.

Q: Are bag filling machines customizable?

A: Yes, bag filling machines can often be customized to meet specific requirements. Depending on the manufacturer, customization options may include adjustable filling speeds, different bag sizes, integration with existing conveyor systems, and additional features like dust collection systems or bag conveyors.

Q: What maintenance is required for a bag filling machine?

A: Regular maintenance is important to keep a bag filling machine in optimal working condition. This may include routine cleaning, inspection of components for wear or damage, lubrication of moving parts, and calibration of the weighing system. It is advisable to follow the manufacturer's maintenance recommendations outlined in the machine's manual.

Q: Where can I purchase a 50 lb bag filling machine?

A: Bag filling machines for grains packing can be purchased from various industrial equipment suppliers, manufacturers, or distributors specializing in packaging machinery. Researching reputable suppliers and contacting them directly is a good starting point to explore available options and obtain price quotes.

In conclusion

The 50 lb bagging machine plays an important role in the field of grain packaging, providing an efficient and precise bagging solution. Its working principle, key functions and specific examples demonstrate its value in improving production efficiency, reducing human error and ensuring product quality. For grain processors, farms and wholesalers, investing in a 50 lb bag filling machine is a critical step in improving the packaging process, enabling reliable grain packaging and meeting market demands.