As the world becomes more environmentally conscious, the automotive industry is also evolving to meet the demand for cleaner and greener vehicles. One of the key components in reducing harmful emissions from diesel engines is the use of automotive urea.

Automotive urea, also known as diesel exhaust fluid (DEF), is a solution that is injected into the exhaust stream of diesel engines. It helps to convert harmful nitrogen oxides (NOx) into harmless nitrogen and water. This process is known as selective catalytic reduction (SCR), and it is becoming increasingly popular in the automotive industry.

PARAMETERS

Capacity : 5L/10L/20L

Packing type : soft bag

Sealing-off : upper and lower side seals

Heat-seal temperature : 120-150 °C

Film width : 810mm

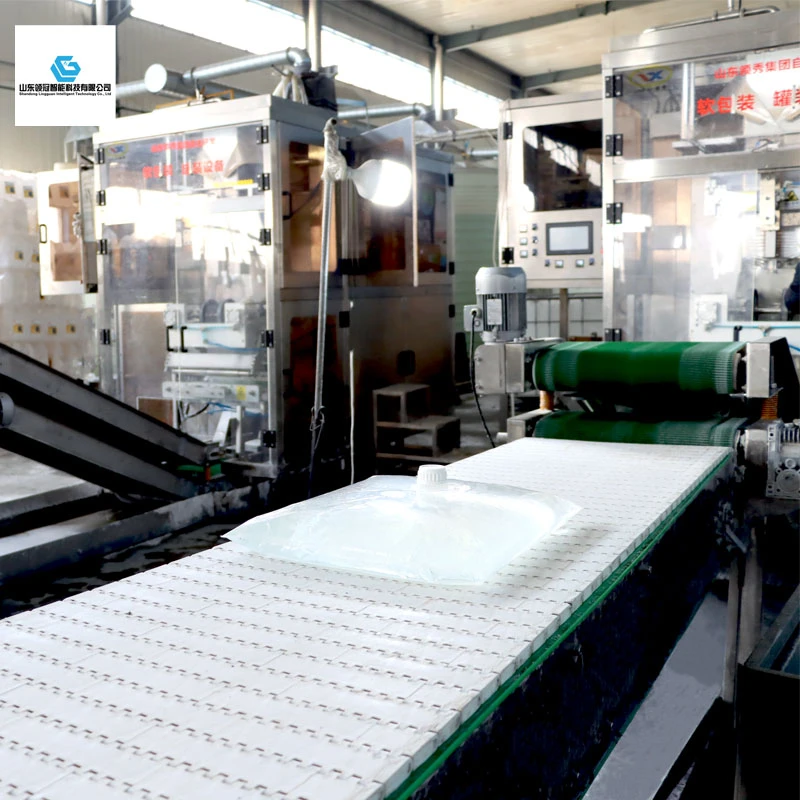

APPEARANCE STRUCTURE

Capping system :

This mechanism consists of a stepper motor, belt, gears, and clamping mechanism. It orderly feeds the lids from the vibrating plate to the lid welding mechanism one by one according to the programmed settings. Its rotation is performed in fixed angles, step by step. The angle displacement can be controlled by adjusting the number of pulses, achieving precise positioning.

Filling system :

The filling system is equipped with one MS250/1.1kw Southern water pump, one frequency converter, and one high-precision photoelectric liquid controller to ensure the accuracy of the filling process.

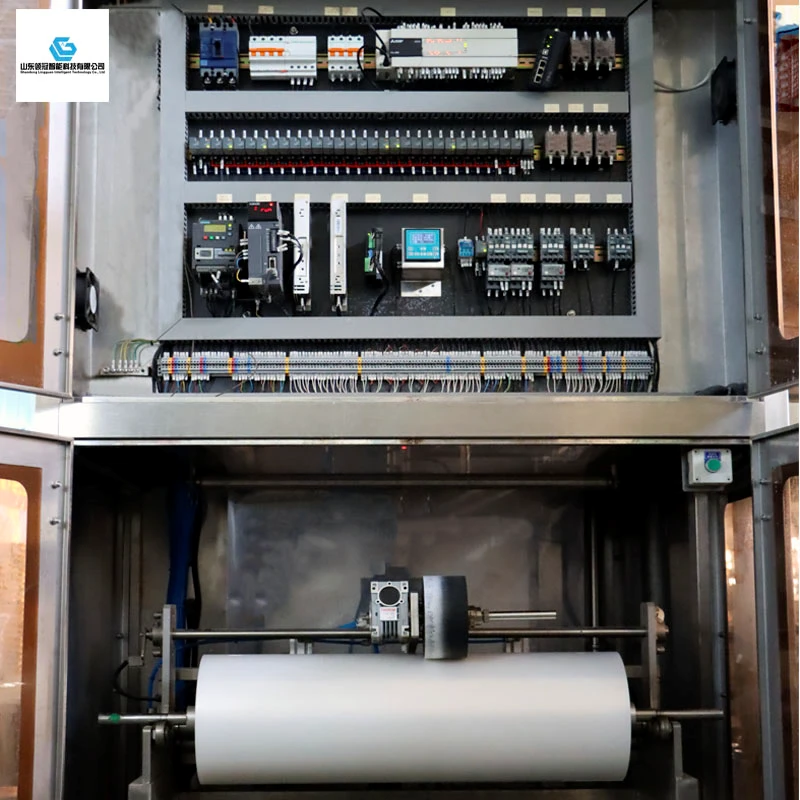

Bag making system :

The film stretching device consists of two components: the transitional film stretching and the positioning film stretching. The transitional film stretching is equipped with a set of film stretching motor and film stretching roller, as well as a film storage component and a color sensor tracking element to complete the transitional film stretching process accurately. The positioning film stretching is equipped with a set of servo motor, two groups of film stretching rollers, and two 80x10 adjustable cylinders, effectively ensuring the size and speed of the film stretching. The collar-shaped molding device is made of imported 304 patterned material, which reduces the resistance of the film during the traveling process and, more importantly, improves the accuracy of the bag size after molding.

Electric system :

The electrical system is composed of components from Schneider Electric, Mitsubishi Electric, Omron Electric, and Stecker Electric. Each process is controlled by a PLC control center through a human-machine interface to meet design requirements. Electrical components, pneumatic components, water pumps, and others use imported or well-known brand components to ensure quality, stability, and practicality of the entire device.

TRANSPORT AND DELIVERY

Tray storage and transportation is convenient for dealers' logistics loading and unloading. It can stack up to 5 boxes high and 9 boxes per layer, with a standard of 45 boxes per tray and a net weight of 0.9 tons. Finally, it is tightly wrapped with multiple layers of protective film.

CONCLUSION

Chinese manufacturers have been investing heavily in research and development to create innovative, efficient, and reliable solutions that meet the needs of the global market. With their affordability, reliability, and ease of use, Chinese automotive urea filling equipment is becoming a popular choice for businesses looking to reduce their operating costs and improve their environmental impact.