What is Bagging liquid filling machine?

A bagging liquid filling machine, also known as a bag-in-box liquid filling machine, is a specialized equipment designed to efficiently and accurately fill liquid products into flexible bags or pouches, commonly used in the bag-in-box packaging format. This type of packaging is popular for various liquid products, including beverages, edible oils, dairy products, sauces, and industrial liquids.

Key Features and Functions:

Bag Handling Mechanism: The machine is equipped with a bag handling system that holds and positions the bags for filling. The bags are typically pre-formed and have a fitment or spout for easy dispensing.

High Precision Filling: The bagging liquid filling machine uses a high-precision filling mechanism to accurately dispense the liquid into each bag, ensuring consistent fill volumes and reducing product wastage.

Aseptic or Non-Aseptic Filling: Depending on the product and packaging requirements, bagging liquid filling machines can be configured for either aseptic or non-aseptic filling processes to maintain product freshness and extend shelf life.

Bag Sealing: After the liquid is filled, the bagging machine seals the bags to prevent leakage and maintain product integrity.

Easy Integration: Bagging liquid filling machines are designed for easy integration into existing production lines or can be used as standalone equipment for smaller operations.

Variable Bag Sizes: The machine can accommodate various bag sizes, allowing for flexibility in packaging volumes and catering to different customer needs.

User-Friendly Controls: Bagging liquid filling machines typically come with user-friendly controls and a Human Machine Interface (HMI) to monitor and adjust the filling parameters and process.

Hygienic Design: Bagging liquid filling machines prioritize hygiene and sanitation, with contact parts made from food-grade materials and designed for easy cleaning and maintenance.

Suitable for Various Liquids: Bagging liquid filling machines can handle a wide range of liquid viscosities, from thin liquids like water and juices to thicker liquids like sauces and oils.

Packaging Material: The machines work with flexible packaging materials, such as bags made from laminated films or foils, which provide excellent barrier properties and help preserve the product's quality.

Applications:

Bagging liquid filling machines are widely used in various industries, including:

Food and Beverage: Packaging of beverages, edible oils, dairy products, sauces, and liquid sweeteners.

Industrial: Filling of chemicals, adhesives, and lubricants in bag-in-box format.

Cosmetics: Packaging of liquid soaps, lotions, and shampoos.

Bagging liquid filling machines offer a cost-effective and efficient solution for packaging liquid products in flexible bags, making them ideal for both small-scale and large-scale production operations.

Device structure

Device structure refers to the physical arrangement and composition of various components within a device. The specific structure of a device can have a significant impact on its functionality, performance, and overall efficiency.

The device has a mechanical structure inside

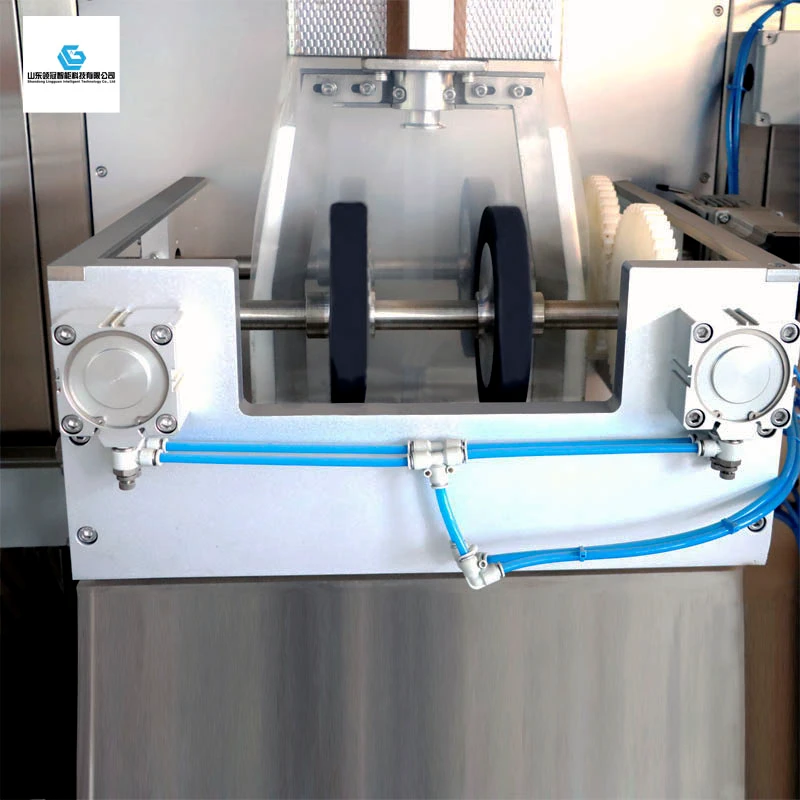

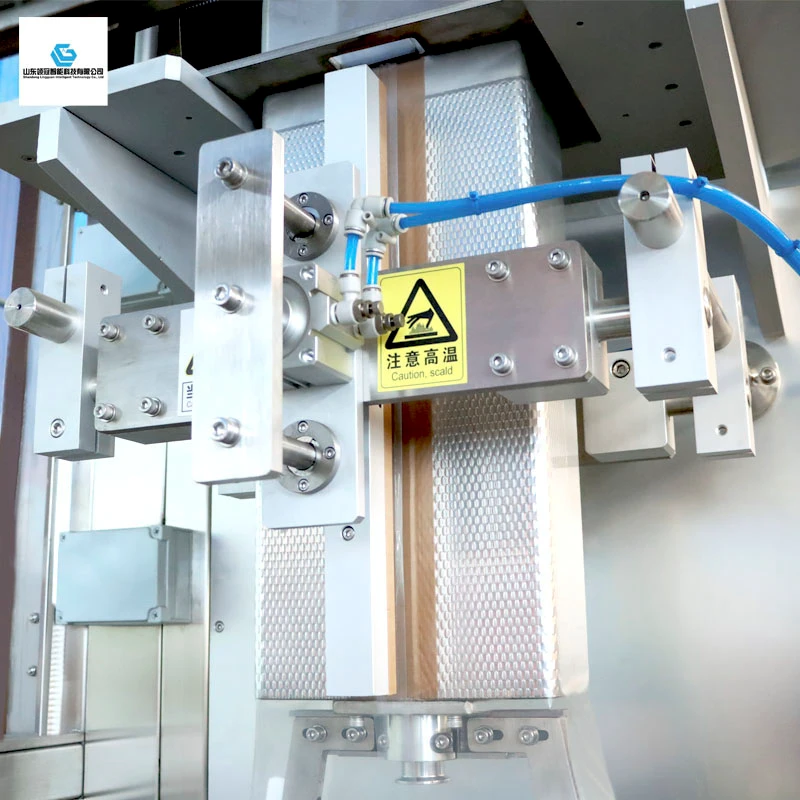

The JGS-810-FE fully automatic water nozzle bagging liquid filling machine consists of a mechanical framework, an automatic film dispensing rack, a semi-automatic film joining device, an automatic welding water seat device, an automatic correction device, a collar forming device, a heat sealing and cutting device, an automatic frequency conversion filling device, an extrusion exhaust device, a sealing cooling device, a film breakage alarm, and an electrical system. Each process is controlled by a PLC control center and is completed smoothly according to the process design requirements through the touch screen.

In summary

In summary, the JGS-810-FE fully automatic water nozzle bagging liquid filling machine is a complex piece of equipment that is made up of various components, including a mechanical frame, film dispensing and joining devices, welding and correction devices, collar forming, sealing, cutting, and filling devices, as well as exhaust and cooling systems. The entire process is controlled by a PLC control center through a touch screen, ensuring accurate and efficient production according to the desired specifications.

FAQ

What types of liquid products can be filled using this machine?

Bagging liquid filling machines can handle a wide range of liquid products, including beverages, edible oils, dairy products, sauces, industrial liquids, and more.

What are the key features of a bagging liquid filling machine?

Key features include high precision filling, easy integration into production lines, variable bag sizes, user-friendly controls, hygienic design, and the ability to handle various liquid viscosities.

Can the machine accommodate different bag sizes?

Yes, bagging liquid filling machines can be adjusted to accommodate various bag sizes, allowing flexibility in packaging volumes.

Is the machine suitable for aseptic filling processes?

Yes, bagging liquid filling machines can be configured for aseptic filling processes to maintain product freshness and extend shelf life.

What type of packaging materials are used for the bags?

Bagging liquid filling machines work with flexible packaging materials, such as laminated films or foils, providing excellent barrier properties for preserving product quality.

Can the machine handle both small-scale and large-scale production?

Yes, bagging liquid filling machines are suitable for both small-scale and large-scale production operations, offering efficient and cost-effective packaging solutions.

How is the filling process controlled?

The filling process is controlled through user-friendly controls and an integrated Human Machine Interface (HMI), allowing operators to monitor and adjust filling parameters.

Is the machine designed for easy cleaning and maintenance?

Yes, bagging liquid filling machines prioritize hygiene and sanitation, with contact parts made from food-grade materials and designed for easy cleaning and maintenance.

What industries use bagging liquid filling machines?

Bagging liquid filling machines are used in various industries, including food and beverage, industrial, and cosmetics, where liquid products are packaged in bag-in-box format.

Can the machine be integrated into existing production lines?

Yes, bagging liquid filling machines are designed for easy integration into existing production lines, streamlining the packaging process.

What type of technical support and after-sales service is provided?

We offer comprehensive technical support, training, and after-sales service to assist our customers in operating and maintaining the bagging liquid filling machines efficiently.

If you have any more questions or need further information about our bagging liquid filling machines, please feel free to contact us. We are dedicated to providing top-quality equipment and solutions for liquid packaging needs.