The demand for liquid beverage filling machines has increased rapidly in recent years, with the growth of the beverage industry. China has responded to this demand by producing high-quality liquid beverage filling machines that are capable of filling a wide range of liquids, such as water, juice, tea, and carbonated drinks.

Feature:

PLC and cloud configuration system make the operation interface simple and clear.

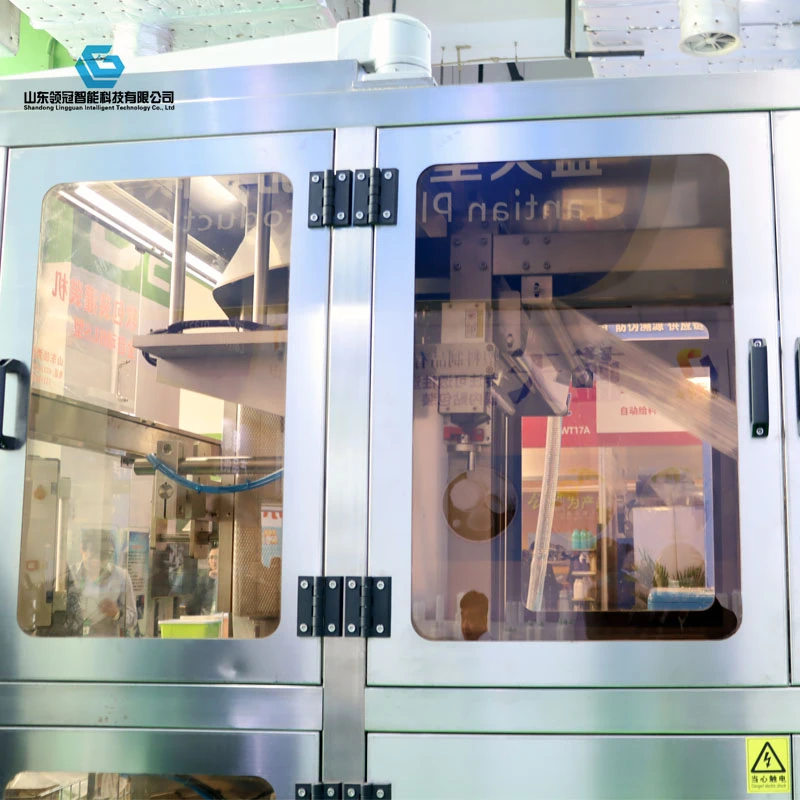

Automatically finish making-bag, metering, filling, sealing, cutting .

The body and the parts touching the material are made of stainless steel.

The finished packed products are elegant and reliable, hygiene and security .

Built-in filtration system, to ensure the purity of the medium .

External printing system to provide logo, LOGO printing . Customization depending on the requirement .

Parameter:

Packaging capacity: ≤360 bags/hour (based on 10 liter bags with water spout)

Filling volume: 10 liters (with water spout as the main product)

Filling accuracy: ±0.5%

Outer dimensions of water spout nozzle: see attached figure for applicable size

Water spout holder: automatically assembled and welded

Heat sealing temperature: 120℃~150℃

Cooling of seal: upper and lower double cooling

Film width: 810mm

Film thickness: suitable for 100μm

Film roll diameter: ≤ø300mm

Cutting: cold cutting (blade made of stainless steel)

In conclusion, China has become a reliable source for liquid beverage filling machines. With its advanced technology, competitive pricing, and strong distribution network, China has been able to establish itself as a major player in the global beverage industry. As the demand for beverages continues to grow, the role of Chinese manufacturers in providing efficient and cost-effective filling machines is expected to become increasingly important.