Filling production line

A complete fruit juice filling production line typically consists of multiple pieces of equipment. These equipment include a water treatment system, a bottle blowing machine, a filling machine, a labeling machine, a packing machine, and a conveyor system. The purpose of this production line is to produce, fill, label, and package bottles of fruit juice. In addition, quality control equipment, such as a leak detector, a weight checker, and a metal detector, may be included in the production line to ensure that the products meet safety and quality standards.

Water treatment system

The water treatment system is an essential component of the production line as it purifies the water used in the production process. This is important as the quality of the water can impact the quality of the final product. The bottle blowing machine is responsible for creating the bottles used in the production line. Once the bottles are created, they are transported to the filling machine, where the fruit juice is added to the bottles. The labeling machine is then used to apply labels to the bottles, which can include branding and nutritional information.

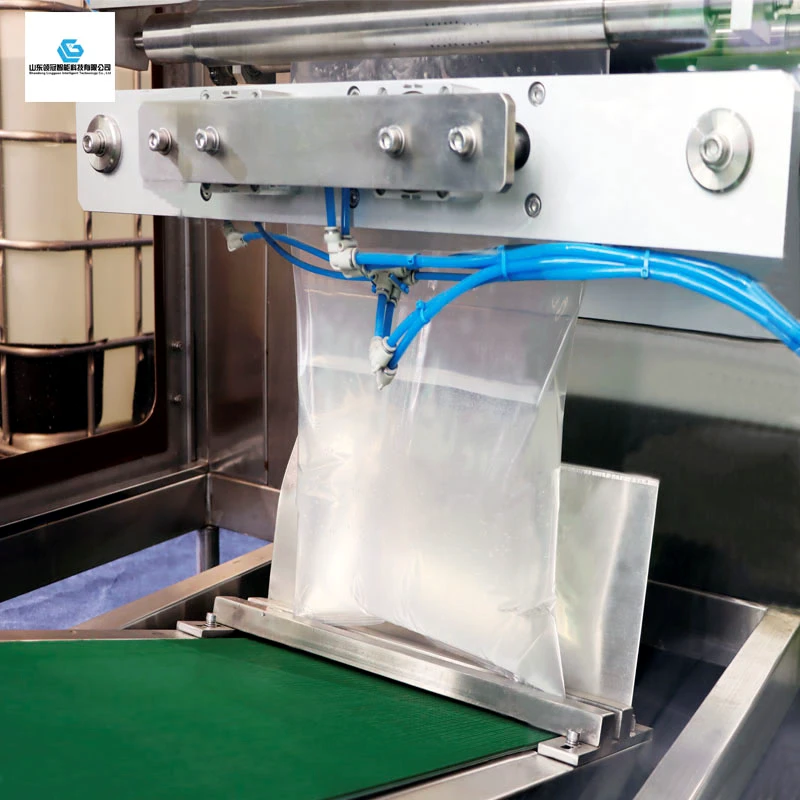

Packing machine

After the bottles are filled and labeled, they are sent to the packing machine, where they are packaged into cases or cartons. The conveyor system plays a vital role in moving the bottles from one machine to the next. The quality control equipment ensures that the final products are safe for consumption and meet quality standards. For example, the leak detector is used to check for any leaks in the bottles, the weight checker is used to ensure that each bottle contains the correct amount of juice, and the metal detector is used to identify any metal contaminants in the product.

In conclusion, a complete fruit juice filling production line is a complex system that requires multiple pieces of equipment to work together seamlessly. This production line plays a crucial role in ensuring that high-quality and safe fruit juice products are available to consumers.