Equipment

A filling packing machine for plastic bags is a highly specialized piece of equipment that is designed to streamline the process of filling and packaging products into plastic bags. This type of machine is commonly used in industries such as food and beverage, pharmaceuticals, and cosmetics, among others.

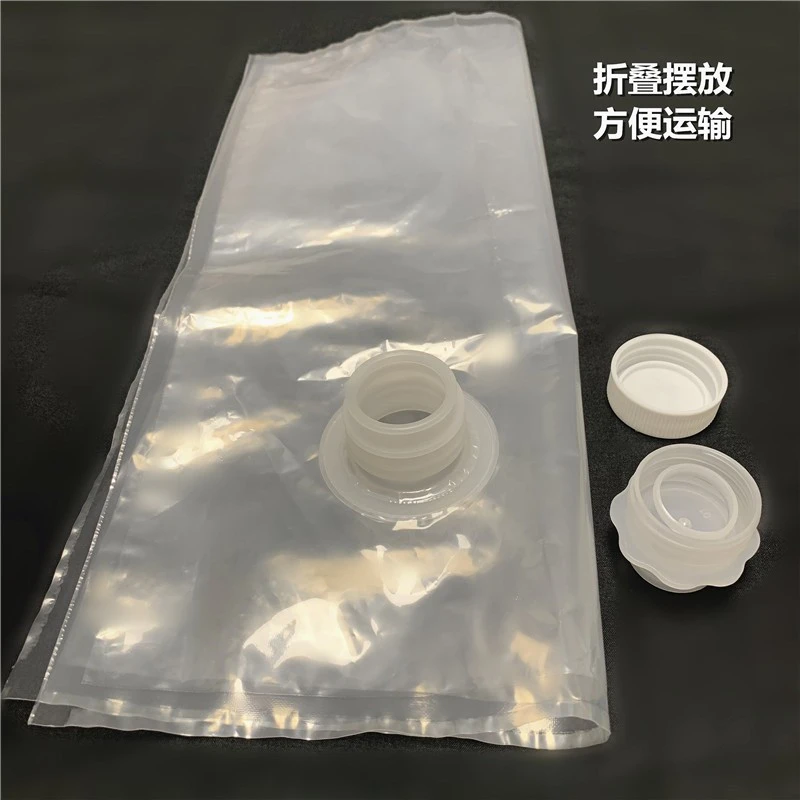

The machine works by automating the entire process of filling bags with the desired amount of product. The bags are first loaded onto the machine, which then fills them with the product using a predetermined amount. Once the bags are filled, they are sealed and prepared for distribution.

Advantages

One of the key advantages of using a filling packing machine for plastic bags is that it greatly reduces the amount of manual labor required for the process. This means that the machine can operate continuously without the need for breaks or rest periods. This leads to increased production efficiency and reduced labor costs.

Another advantage of using a filling packing machine for plastic bags is that it allows for greater precision and accuracy in the filling process. The machine is able to fill each bag with the exact amount of product, ensuring consistency in the final product. This is particularly important in industries such as pharmaceuticals, where accuracy is crucial.

Different types of filling packing machines

There are several different types of filling packing machines available on the market, each with its own unique features and capabilities. Some machines are designed to fill bags with dry products such as powders or granules, while others are designed for liquids or semi-liquids.

In addition to filling and sealing bags, some machines are also capable of printing expiration dates, lot numbers, and other information directly onto the bag. This helps to ensure that the product is properly labeled and tracked throughout the distribution process.

Overall, a filling packing machine for plastic bags is an essential piece of equipment for any industry that requires the efficient and accurate packaging of products. By automating the process, these machines help to reduce labor costs, increase production efficiency, and ensure consistency in the final product.