The Flexpack Liquid Filling Machine is equipped with advanced features that make it a reliable and versatile solution for liquid packaging. One of its key functions is its ability to fill a wide range of container sizes and shapes, from small bottles to large containers. The machine is also designed to handle different types of liquids, including those with varying viscosities and densities.

OPERATING INSTRUCTIONS FOR A FLEXPACK LIQUID FILLING MACHINE

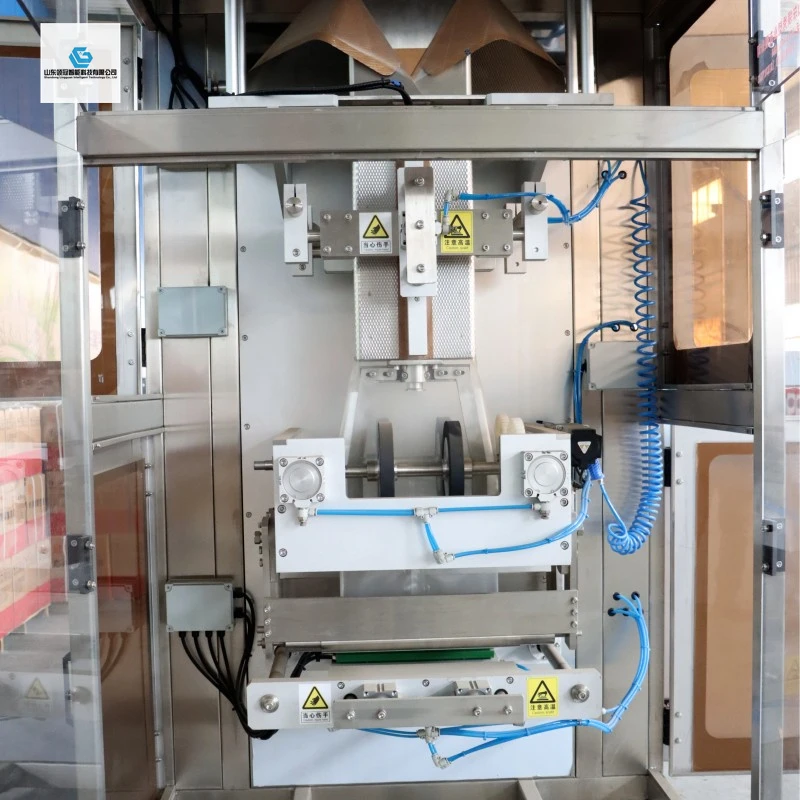

1. The operator must be familiar with the basic structure, basic performance, and uses of this equipment. They must also be familiar with adjusting the output, temperature, and packaging quality, as well as the various instructions and indications on the touch screen and their functions.

2 . Before starting the machine:

Lubricate the lubrication points.

Check if the film on the film feeding rack is in the central position. The film feeding roller should press the film roll. After the film enters the traction wheel, open the lower door to check if the tightness of the film on both sides is consistent.

Check if the liquid in the ultrasonic water tank is at the appropriate level.

Check if the product water in the immersion sterile water tank has reached the required level.

Adjust the pressure regulator pointer to the 115V~160V scale line, and the heat sealing temperature must reach the required temperature.

When installing the water outlet holder for production, check if the water outlet holder has been added to the lid opener.

3 . After turning on the main power switch, touch the display screen. When the manual or automatic operation screen appears, open the system operation instructions and follow the instructions.

4 . Startup sequence:

Turn on the main power switch → touch the temperature (middle seal, horizontal seal) instruction on the touch screen → touch the heating instruction → touch the single action instruction → traction → middle seal (after two middle seals) → touch the horizontal seal instruction, then touch the start instruction (the equipment will work in full automatic mode).

If a malfunction occurs during the production process, immediately press the emergency stop switch on the touch screen. After the malfunction is resolved, follow the startup sequence to restart the machine.

OVERALL

The Flexpack Liquid Filling Machine has a wide range of applications across various industries . It is ideal for small to medium-sized businesses that require a reliable and efficient liquid filling solution. With its advanced features and benefits, the Flexpack Liquid Filling Machine is a valuable investment for any business looking to improve their liquid packaging process.