When it comes to liquid filling machines, the parts are crucial to the overall functionality and efficiency of the machine. In China, there are many manufacturers of liquid filling machine parts, each with their own unique structures and designs.

Unfortunately, liquid filling machine parts are not immune to damage. Over time, parts can become worn or damaged, leading to decreased performance and potentially costly repairs. It is important to regularly inspect and maintain liquid filling machine parts to ensure they are functioning properly and to prevent any potential damage.

When it comes to purchasing liquid filling machine parts in China, there are many options available. It is important to do your research and choose a reputable manufacturer that produces high-quality parts. Look for manufacturers that have a proven track record of producing reliable and durable parts.

SOME PARTS OF LIQUID FILLING MACHINE

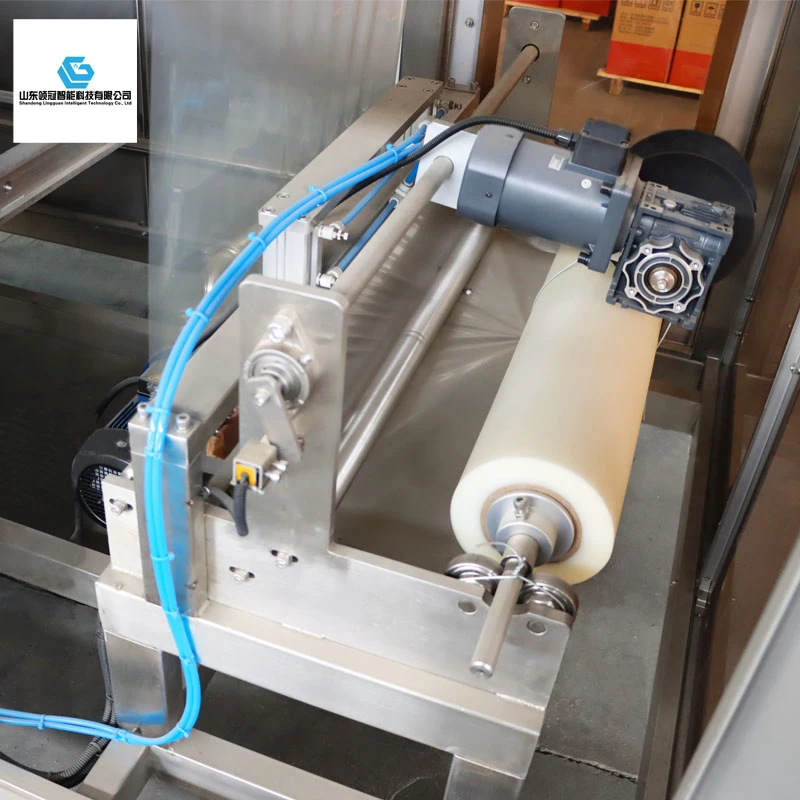

The film stretching device consists of two components: the transitional film stretching and the positioning film stretching. The transitional film stretching is equipped with a set of film stretching motor and film stretching roller, as well as a film storage unit and a color mark sensor tracking element to ensure the correct completion of the transitional film stretching process. The positioning film stretching is equipped with a set of servo motor, two groups of film stretching rollers, and two 80×10 adjustable pneumatic cylinders, effectively ensuring the length and speed of the film stretching.

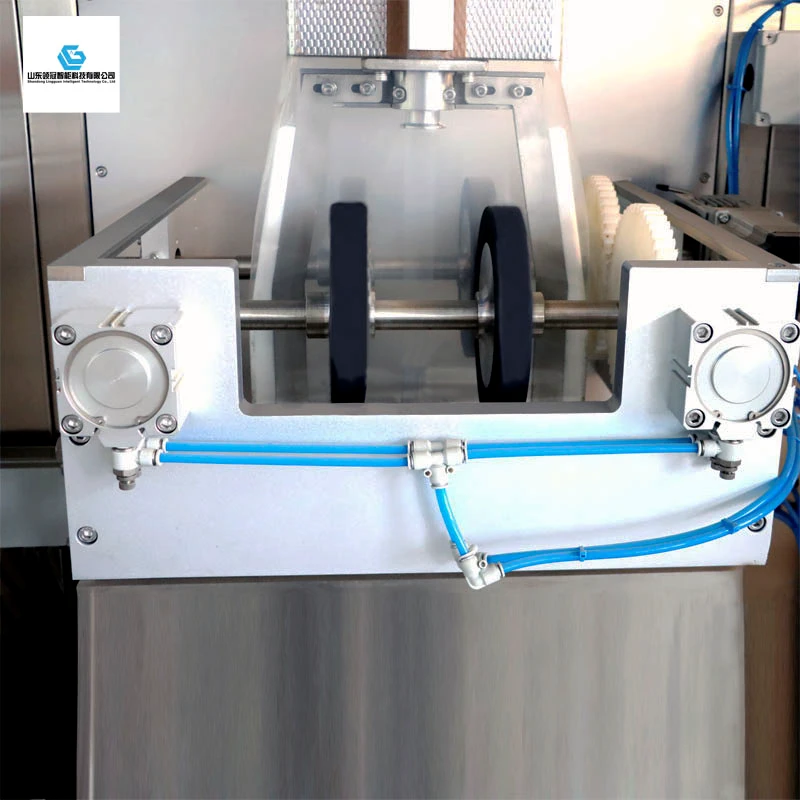

The heat sealing and cold cutting device consists of vertical sealing, horizontal sealing, cold cutting, and seal cooling. The vertical sealing is equipped with four 50×25 Airtac cylinders and a vertical sealing device to complete the vertical sealing process. The horizontal sealing is equipped with two 100×100 Airtac cylinders, four 63×25 Airtac cylinders, horizontal sealing and auxiliary sealing devices, as well as tube-shaped heating pipes and Omron temperature controllers to complete the horizontal sealing process. The cold cutting is equipped with two 25×15 Airtac cylinders and a highly wear-resistant cutting blade to complete the cold cutting process. The seal cooling is equipped with insulation and air cooling to ensure a smooth and wrinkle-free seal with clear contours and no water leakage.

In conclusion, liquid filling machine parts are a crucial component of any liquid filling machine. In China, there are many options available for purchasing high-quality parts, but it is important to choose a reputable manufacturer and prioritize quality over cost. By regularly inspecting and maintaining your liquid filling machine parts, you can ensure that your machine is functioning at its best and avoid any potential damage or costly repairs.