China is a hub of innovation and technology, and the liquid filling and sealing machine industry is no exception. With a wide range of models and types available, Chinese liquid filling and sealing machines are known for their precision, efficiency, and reliability.

TYPES

There are many different types and models to choose from. Some of the most common types include volumetric fillers, piston fillers, and gravity fillers. Each type has its own unique advantages and is suited to different applications.

For example, volumetric fillers are ideal for filling liquids of different viscosities, while piston fillers are best suited to filling thicker liquids such as creams and pastes. Gravity fillers, on the other hand, are ideal for filling thin liquids such as water and juice.

FEATURES for a liquid sealing filling machine

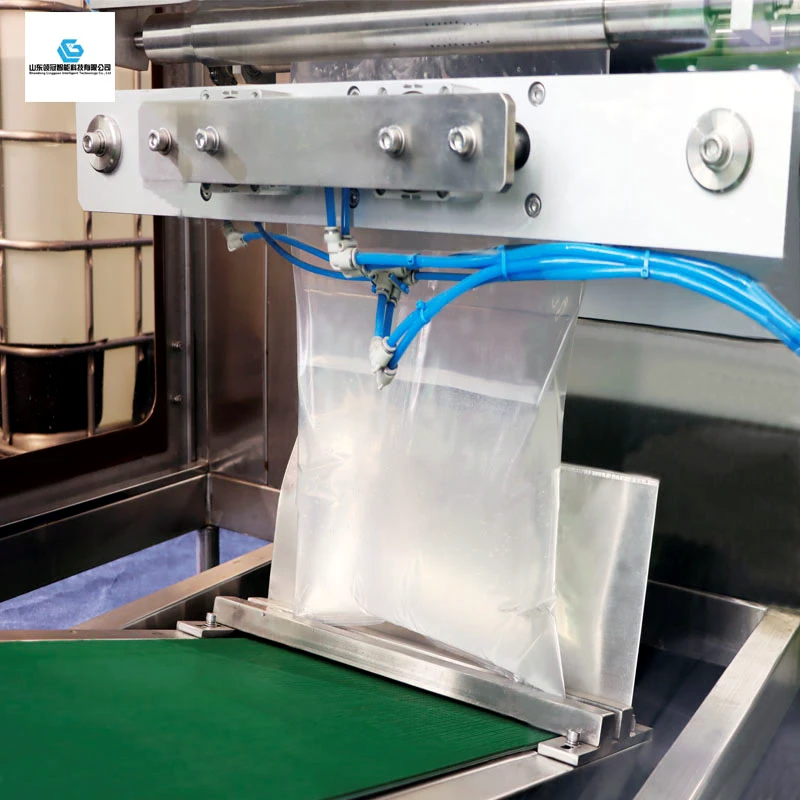

The single bag soft packaging has a net weight of 10kg and is used with a transit box, allowing customers to complete the product packaging, loading, and unloading faster.

The transit box is lightweight and stackable, saving storage space for empty boxes and reducing transportation costs when returning the boxes. The transit box can hold up to 40kg, with 5 boxes in perfect condition, increasing product stacking density, shipment quantities, and reducing transportation costs.

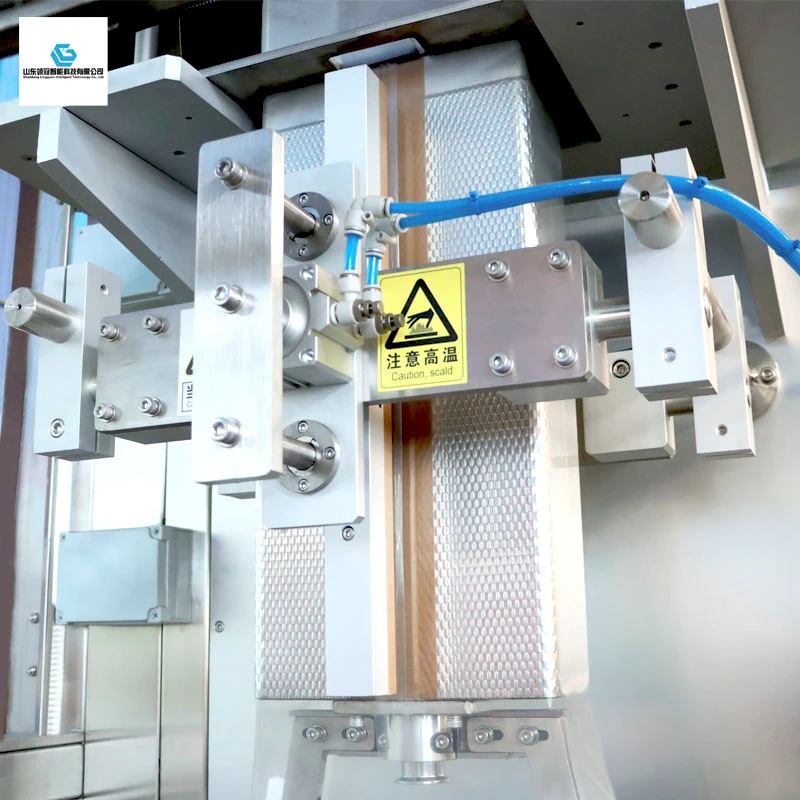

The sealing system is composed of a 304 frame, automatic lid feeder, vibrating chute, SMC cylinder, precise synchronous belt stepper motor, heating thermostat, and electrical control components to complete the lid feeding, positioning, and welding process.

The fully automatic spout machine performs automatic positioning, punching, welding, and filling of the spout.

IN SUMMARY

The liquid sealing and filling machines have various applications in different industries. They are widely used in the beverage, pharmaceutical, and chemical industries, among others. With its advanced features and high-quality production, it has become an essential tool for businesses looking to increase their production capacity and improve their product quality.