China is known for manufacturing some of the most affordable and reliable equipment in the world. Their numerical control liquid filling machines are no exception. Many manufacturers in China offer customized solutions tailored to your specific needs, making it a great option for small to medium-sized businesses.

NUMERICAL STRUCTURE and COMPOSITION

The structure of the fully automatic water outlet connector is composed of a 304 frame, a fully automatic lid lifter, a vibration slide, a Festo cylinder, a precision synchronous belt stepper motor, heating and temperature control components, and electrical control elements to complete processes such as lid lifting, lid feeding, and positioning welding.

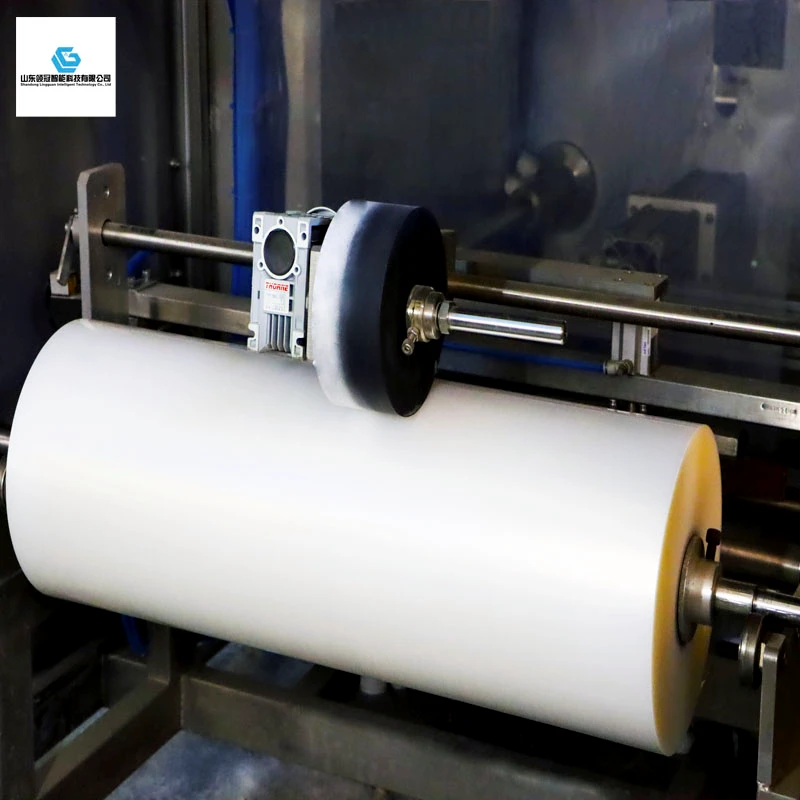

The film frame is equipped with a set of film storage structure and film break alarm device to properly complete the automated process of film placement and storage.

The semi-automatic film laminating device consists of a pressure regulator, transformer, two 40x25 Airtac cylinders, and a nickel-chromium wire bracket to complete the film lamination process during film changing and ensure that the film is not contaminated.

The correction device is equipped with three lever rollers, a correction stepper motor, and a set of precision sliding tables, effectively automatically correcting the alignment of the film, ensuring that the film is in the appropriate position during production.

No matter where you are in the world, a numerical control liquid filling machine is a great investment for your business. These machines offer unparalleled accuracy and efficiency, allowing you to save time and money while improving the quality of your products.