Soft bag packaging filling machinery for 20L is typically used in the food and beverage industry, as well as in the pharmaceutical and chemical sectors. It is ideal for packaging products such as coffee, tea, powders, sauces, and liquids. The machine is fully automated, with programmable controls that allow for accurate filling and sealing of the bags.

Characteristics of the soft bag packaging and filling machinery for 20L

Types of various bags applicable: for example, pillow bags, component installation bags, flat bracket bags, and so on.

The adjustable bag size and weight are easy to change the bag in the previous minute without complicated processes.

Panasonic PLC control system, Siemens human -machine touch screen.

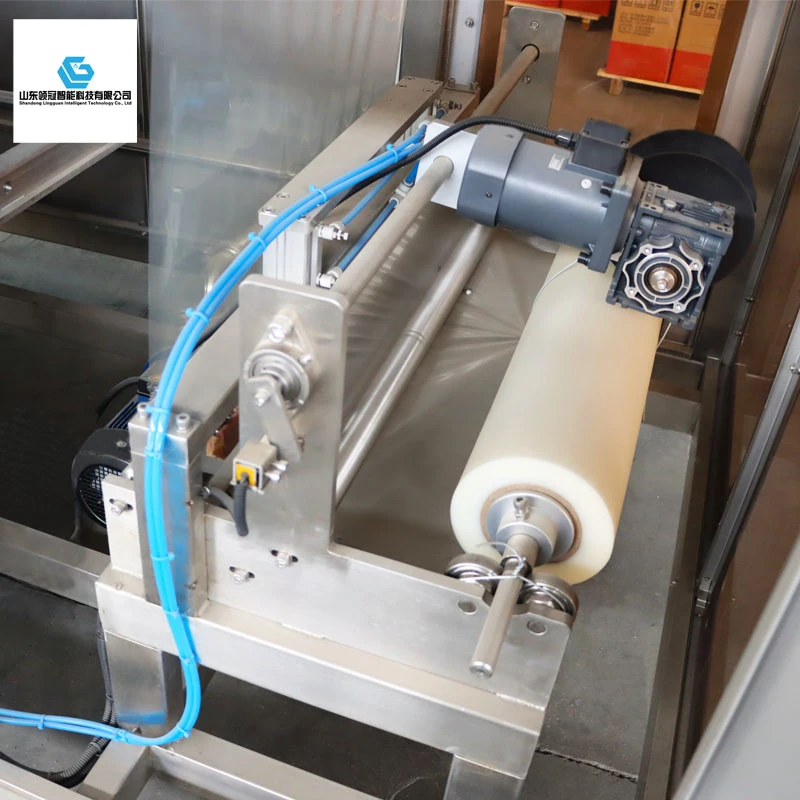

The servo motor enables this machine to achieve accurate positioning, stable speed, and stability operation.

Using automatic alarm protection function can minimize losses.

Automatic measurement, eating, filling, cover, bag production, printing.

Food -grade stainless steel 304, safe and durable.

Vertical sealing temperature controller: Each heating block is controlled by a single temperature controller to achieve higher temperature stability.

Broken film alarm system, early warning, ensuring connectivity .

Options

1. Date printer

2. Pole perforation

3. Gas rinse

4. Eating and takeaway conveyor

5. Metal detector

In summary , the soft bag packaging and filling machinery is a type of packaging machinery that is designed to fill soft bags with various products. This machine is commonly used in the food and beverage industry, as well as in pharmaceutical and cosmetic manufacturing.