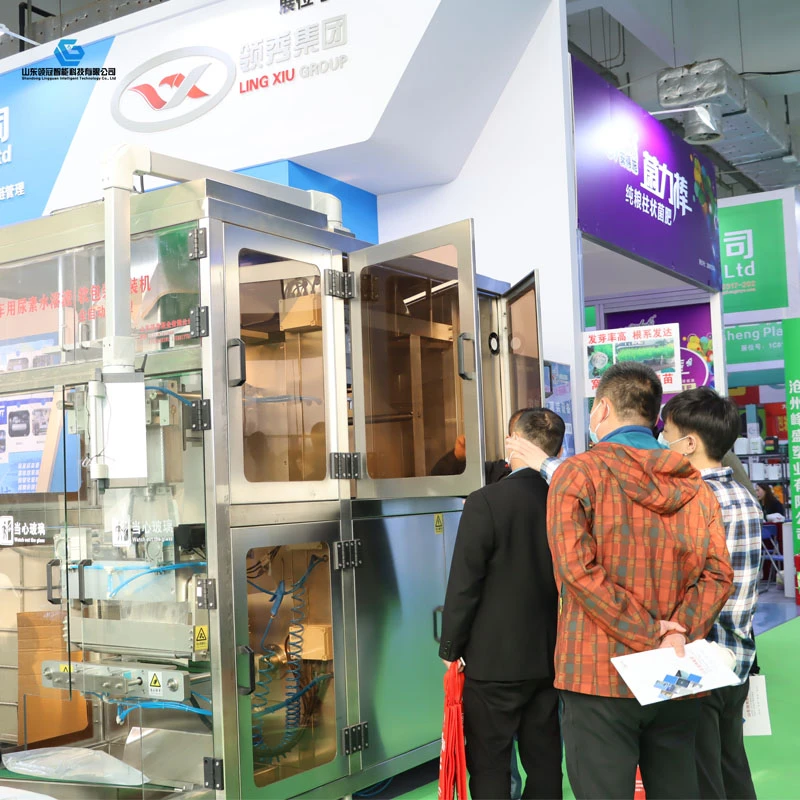

Anti-corrosion filling machine

The anti-corrosion filling machine is used to fill corrosive liquids, such as acids, alkalis, and other aggressive chemicals, into containers without causing damage to the equipment or the product being filled. The machine is typically made of materials that are resistant to corrosion, such as stainless steel or plastic. Its design includes special features, such as corrosion-resistant pumps and valves, to ensure that the filling process is safe and efficient. The anti-corrosion filling machine is commonly used in industries such as chemical manufacturing, pharmaceuticals, and agriculture, where the handling of corrosive liquids is necessary.

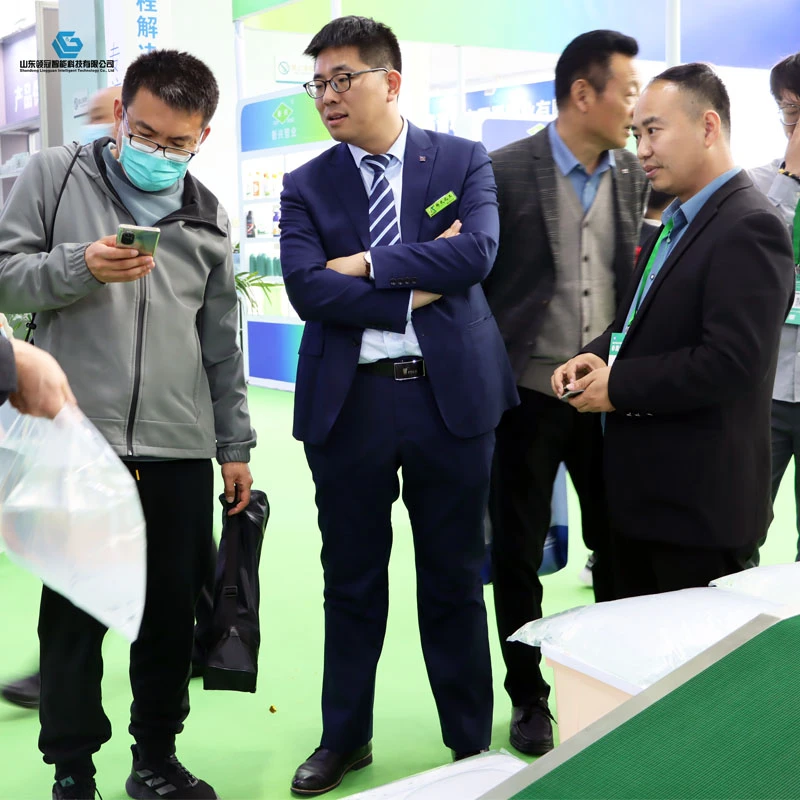

The market for anti-corrosion filling machines

The market for anti-corrosion filling machines is driven by the demand for safe and efficient filling of corrosive liquids in various industries, such as chemical, pharmaceutical, and agricultural. The increasing need for preventing equipment damage and ensuring product quality has led to the adoption of anti-corrosion filling machines. The market is expected to grow due to the expanding chemical and pharmaceutical industries, particularly in emerging economies. The key players in the market are focusing on developing advanced anti-corrosion filling machines that offer better efficiency and durability. Furthermore, increasing environmental regulations and safety standards are expected to boost the demand for anti-corrosion filling machines in the future.

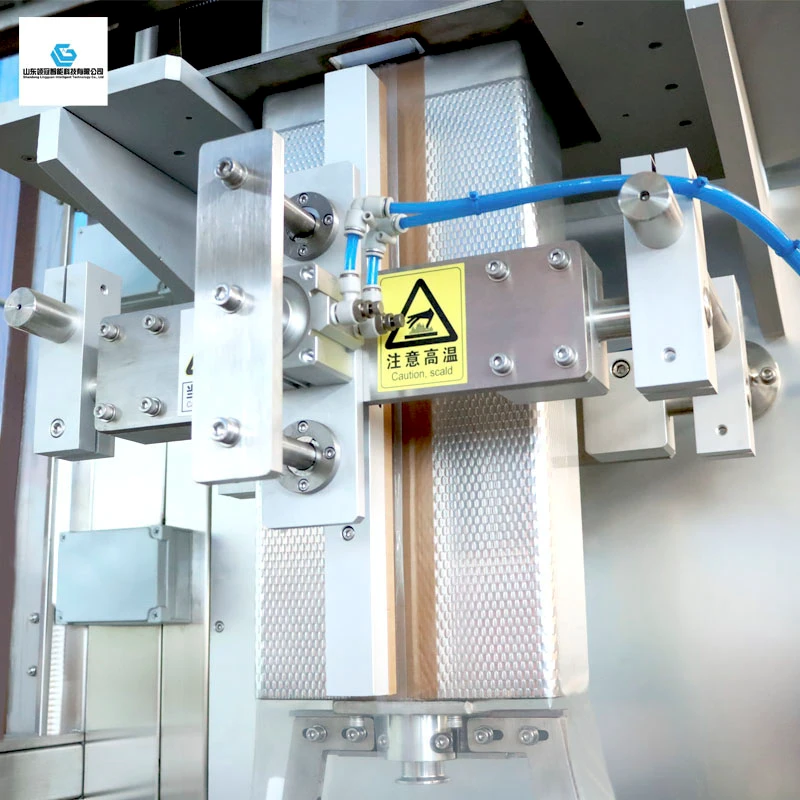

The advantages of anti-corrosion filling machines

The advantages of anti-corrosion filling machines include their ability to handle corrosive liquids without causing equipment damage or compromising product quality. They are made of materials that are resistant to corrosion, such as stainless steel or plastic, which makes them durable and long-lasting. Anti-corrosion filling machines also feature corrosion-resistant pumps and valves, which ensure safe and efficient filling of corrosive liquids. Additionally, they can be customized to meet specific filling requirements and can be integrated into existing production lines. These machines are essential for industries that handle corrosive liquids and help to ensure the safety of workers and the environment.