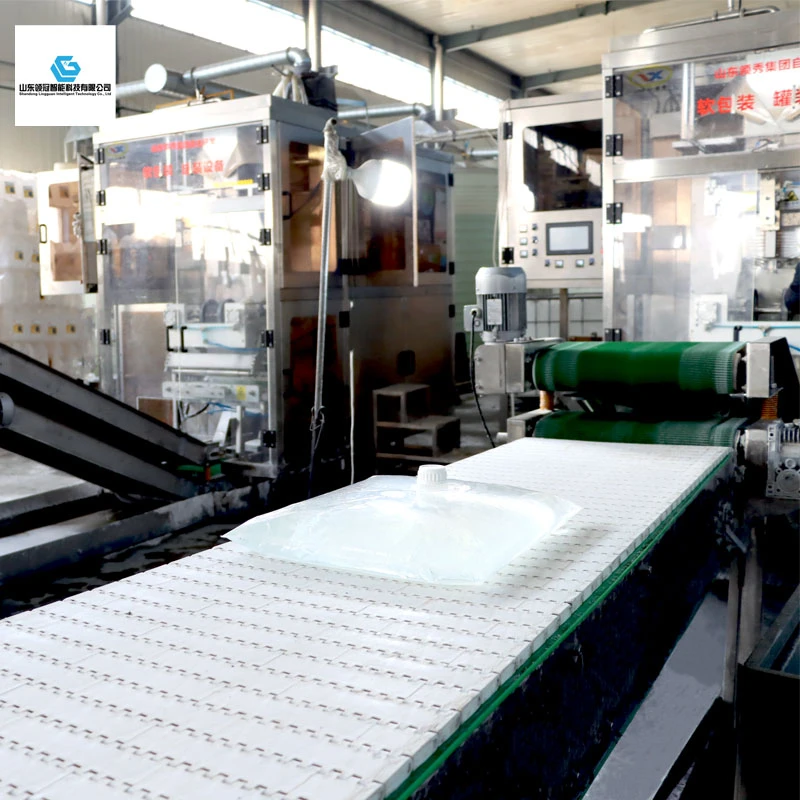

The big pouch filling machine is a highly efficient piece of equipment that can fill large volumes of soft bags quickly and accurately. It is designed to handle products that are in liquid form, such as juices, oils, and syrups, as well as those that are in powder or granular form, such as coffee, flour, and sugar.

OPERATIONAL DETAILS for the big pouch filling machine

Semi-automatic film laminating device: When one roll of film is used up, the next roll is used and the ends of the upper and lower rolls are placed flat on the heat sealer. Press the "film laminating heating" button on the touch screen to activate.

The extrusion exhaust system is powered by the film pulling motor. If there is still a lot of air in the water bag, the position of the photoelectric sensor and the reflux ball valve must be adjusted to ensure that there is very little air in the water bag.

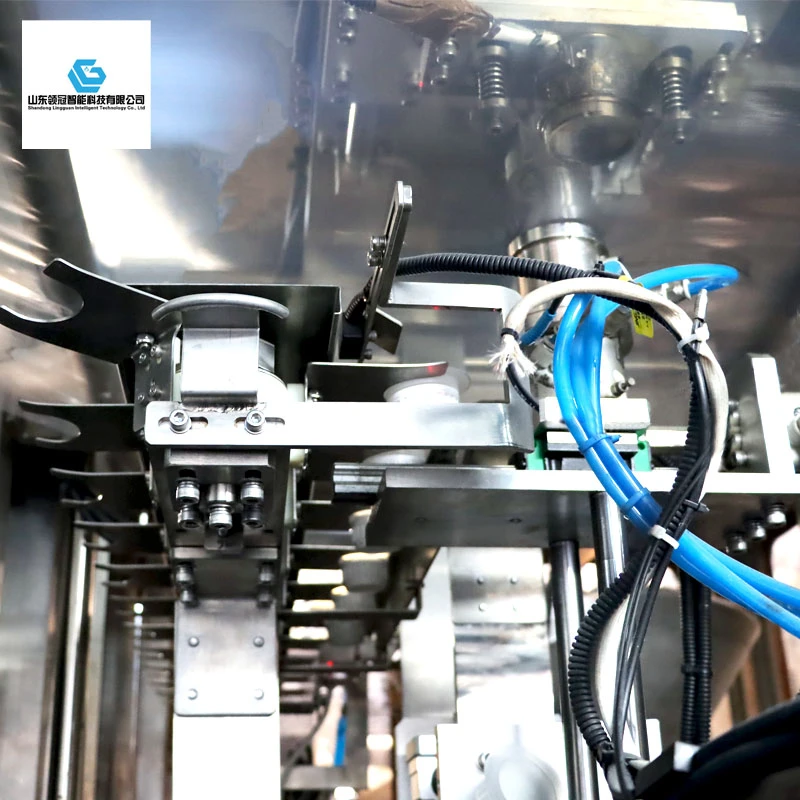

The fully automatic connection water nozzle seat structure first requires placing about 300 qualified water nozzle seats into the lid placer, then turning on the automatic switch, and the subsequent lid placing, feeding, heating, positioning, and welding will be automatically completed according to the preset program for the welding process.

ADVANTAGES

The big pouch filling machine is that it can be customized to meet the specific needs of different industries. For example, it can be designed to handle bags of different sizes and shapes, or to fill bags with different types of products at the same time.

The big pouch filling machine is that it is easy to operate and maintain. It comes with user-friendly controls and can be easily cleaned and serviced, ensuring that it operates smoothly and efficiently.

Overall, the big pouch filling machine is an essential piece of equipment for any business that needs to fill soft bags with large volumes of products quickly and accurately. With its high efficiency, customization options, and ease of use, it is a valuable investment for any industry.