Industries

A drinking water producing bagging filling machine line is a highly specialized piece of equipment that is designed to streamline the process of filling and packaging drinking water into bags. This type of machine is commonly used in industries such as bottled water production, beverage production, and water treatment plants.

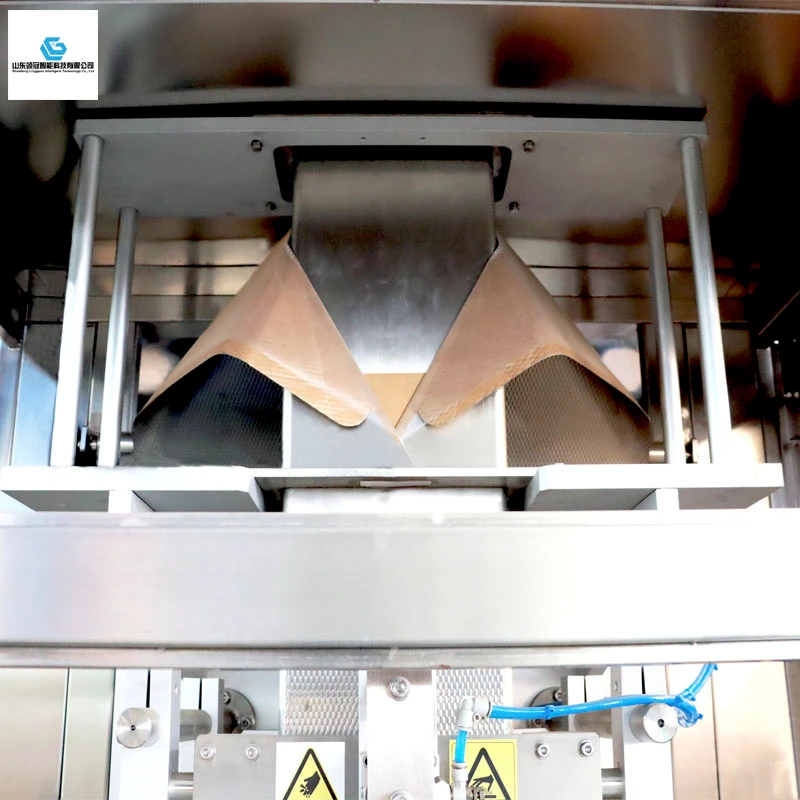

The machine works by automating the entire process of filling bags with the desired amount of drinking water. The bags are first loaded onto the machine, which then fills them with the water using a predetermined amount. Once the bags are filled, they are sealed and prepared for distribution.

We are honored to introduce our bulk drinking water filling production line to you. As a professional manufacturer, we are committed to providing you with high-quality, high-efficiency filling solutions to meet the growing market demand for large-package drinking water.

Features:

Large packaging adaptability: Our filling production line is specially designed for large packaging of drinking water (such as 5 liters, 10 liters, 18 liters, etc.), which can meet the packaging requirements of different capacities.

Automated operation: Our production line adopts advanced automatic control system to realize the automatic operation of the whole filling process, from filling to sealing, making the production process efficient and stable.

High flexibility: The production line is suitable for different types of packaging materials, such as PE bags, coated bags, etc. Customized configurations can be made according to customer needs to meet different packaging specifications and forms.

High-precision metering: Our filling system is equipped with precision metering devices to ensure that the filling volume of each packaging unit is accurate, avoiding waste and saving costs.

Sanitation and safety: The production line adopts stainless steel materials and components that meet hygienic standards to ensure the sanitation of the filling process and the safety of products.

Easy to operate: The production line is simple in design, easy to operate and maintain, so that operators can easily get started and improve production efficiency.

Customized service: We provide customized production line design and configuration, according to the special needs and requirements of customers, to ensure that your production requirements are met to the greatest extent.

After-sales support: We have a professional after-sales team to provide you with timely technical support and maintenance services to ensure the long-term stable operation of the production line.

Our large-package drinking water filling production line has won unanimous praise from domestic and foreign customers for its excellent performance, high-efficiency production capacity and reliable quality. Whether you are building a new plant or expanding production capacity, we have suitable filling solutions, welcome to contact us, let us inject new vitality into your production line together!

Advantages

One of the key advantages of using a drinking water producing bagging filling machine line is that it greatly reduces the amount of manual labor required for the process. This means that the machine can operate continuously without the need for breaks or rest periods. This leads to increased production efficiency and reduced labor costs.

Another advantage of using a drinking water producing bagging filling machine line is that it allows for greater precision and accuracy in the filling process. The machine is able to fill each bag with the exact amount of water, ensuring consistency in the final product. This is particularly important in industries such as bottled water production, where accuracy is crucial.

There are several different types of drinking water producing bagging filling machines available on the market, each with its own unique features and capabilities. Some machines are designed to fill bags with a specific volume of water, while others are designed to fill bags with a specific weight of water.

In addition to filling and sealing bags, some machines are also capable of printing expiration dates, lot numbers, and other information directly onto the bag. This helps to ensure that the product is properly labeled and tracked throughout the distribution process.

How should I care for this Bagging Filling Machine Line?

Caring for the Drinking Water Producing Bagging Filling Machine Line is very important to keep its production running stably and efficiently. Here are some suggestions and steps to help you properly maintain your machine:

Regular cleaning is key to keeping your production line running well. After each use, thoroughly clean the exterior and interior parts of the machine, especially parts in contact with liquids. Use appropriate cleaning agents and tools to ensure that residue and dirt are thoroughly removed.

It is very important to maintain the lubrication status of the various moving parts of the machine. Follow the instruction manual provided by the line manufacturer to periodically check and relubricate to ensure smooth operation of the components.

Regularly check the bolts, screws and other connecting parts on the machine to ensure that they are firmly connected. Avoid loose situations to prevent unnecessary damage.

During production line operation, certain parts may experience wear. Check and replace worn parts in time, such as sealing rings, O-rings and valves, etc., to ensure the stability and sealing of the equipment.

Regularly check the sensors and automatic control systems on the machine to make sure they are working properly. Faulty sensors or controllers can cause line downtime or production quality issues.

Keep a clean and tidy working environment around the production line to prevent dust and dirt from entering the inside of the machine and affecting its performance.

Make sure operators are adequately trained in the proper operation and maintenance of the machine. Proper operation and maintenance can extend the life of equipment and ensure safety.

Perform regular maintenance and maintenance according to the equipment manufacturer's recommendations. Regular maintenance includes checking and replacing wearing parts, adjusting equipment, calibrating sensors, etc.

Record the date, content and details of each maintenance to help track the maintenance history and performance of the equipment.

By following the maintenance measures above, you can ensure the reliability, stability and efficiency of your Drinking Water Producing Bagging Filling Machine Line. Proper maintenance will help extend the life of your equipment and provide you with continued high-quality production.

Filling machine line

Overall, a drinking water producing bagging filling machine line is an essential piece of equipment for any industry that requires the efficient and accurate packaging of drinking water. By automating the process, these machines help to reduce labor costs, increase production efficiency, and ensure consistency in the final product.

FAQ

1. What is a Drinking Water Producing Bagging Filling Machine Line?

A Drinking Water Producing Bagging Filling Machine Line is a specialized production line designed to fill and package drinking water into large bags (e.g., 5 liters, 10 liters, 18 liters) in an automated and aseptic manner.

2. What types of packaging can this machine line handle?

This machine line is designed to handle large packaging formats, primarily using bags made of materials such as PE (polyethylene) and coated films. It can efficiently package various volumes of drinking water to cater to different market demands.

3. How does the machine ensure the quality of the drinking water during the filling process?

The machine line incorporates advanced quality control measures, such as precision measurement devices and sensors, to ensure accurate filling volumes and airtight sealing. These measures guarantee the high quality and safety of the packaged drinking water.

4. Can this machine line be customized to accommodate different bag sizes and packaging requirements?

Yes, the Drinking Water Producing Bagging Filling Machine Line can be customized to handle different bag sizes and packaging formats. Manufacturers can choose from a range of bag sizes and configurations to suit their specific production needs.

5. Is the machine line easy to operate and maintain?

Yes, the machine line is designed with user-friendliness in mind. It features easy-to-use interfaces and automated functions, making it simple for operators to control and monitor the filling process. Regular maintenance routines are also straightforward and help keep the machine in optimal condition.

6. How does the machine ensure the safety and hygiene of the drinking water?

The machine line is constructed with stainless steel and components compliant with hygiene standards, ensuring that the drinking water remains uncontaminated during the filling and packaging process. Additionally, the automated aseptic filling process minimizes the risk of contamination.

7. What is the production capacity of the machine line?

The production capacity of the machine line varies depending on the model and configuration. It can be tailored to match the production requirements of different manufacturers, with varying levels of output capacity.

8. Does the machine line require specific training for operators?

Yes, operators should receive proper training on how to operate and maintain the machine line correctly. This training ensures smooth and efficient production and reduces the likelihood of errors or accidents.

9. Can this machine line be integrated into existing production facilities?

Yes, the Drinking Water Producing Bagging Filling Machine Line can be integrated into existing production facilities with proper planning and adjustments. Manufacturers can discuss customization options with the machine supplier to ensure seamless integration.

10. Is technical support and after-sales service available for the machine line?

Yes, reputable machine manufacturers offer technical support and after-sales services to assist with installation, training, maintenance, and troubleshooting to ensure the machine's long-term reliability and efficiency.